Innovative Technology

Green & Energy-Saving Factor

Battery module testing and production is an energy-intensive process. To improve efficiency, our production lines are fully equipped with energy-recovery discharge systems, supported by a 100 kW energy buffering storage unit. By utilizing time-shifted energy supply and storage during charge and discharge cycles, we significantly reduce peak electricity demand during manufacturing operations.

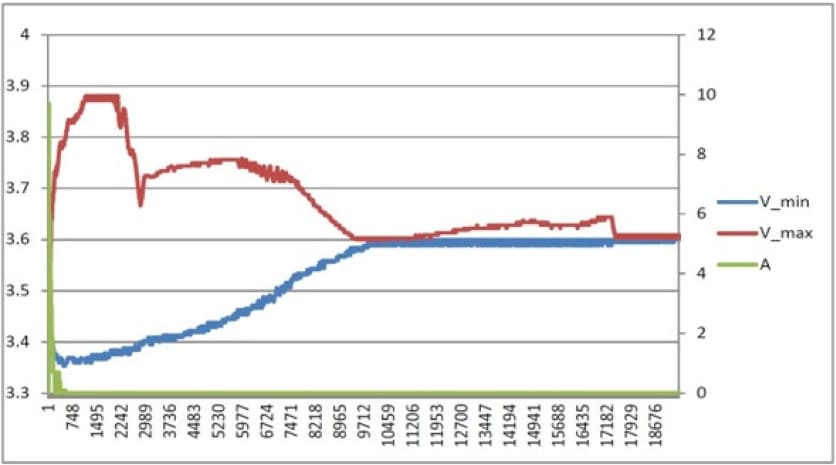

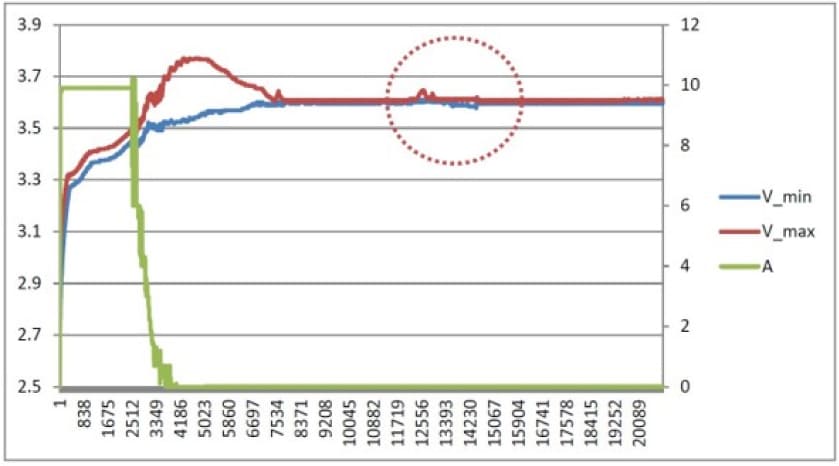

Intelligent Balancing System

Through multiple charge-discharge cycles, our protection board continuously monitors key parameters and dynamically adjusts balancing algorithms. During each subsequent charging phase, the system refines its balancing strategy in real time to optimize both battery lifespan and performance.

Advanced Monitoring System

An integrated engineering mode allows rapid diagnostics of cell status and supports remote control commands. The system also features non-contact precision current sensing and accurate capacity estimation for enhanced operational insights.

Redundant & Layered Structure

Our multi-level battery management system (BMS) adopts a structured and hierarchical design, enabling real-time and organized control across energy storage systems. This approach enhances product scalability, quality consistency, and cost-efficiency for large-scale deployment.

Comprehensive Protection

The first-level BMS and VMS module protection boards offer full-spectrum protection functions. They comply with IEC 60730, UL 1998, and UL 991 functional safety standards, incorporating self-diagnostics, mutual monitoring, and secondary protection mechanisms to ensure system integrity.